$53.99 Original price was: $53.99.$37.79Current price is: $37.79.

- Free Shipping, Quality Goods

- Quality You Can Trust

- Quality products, fair prices.

- Expertly Sourced, Quality Guaranteed

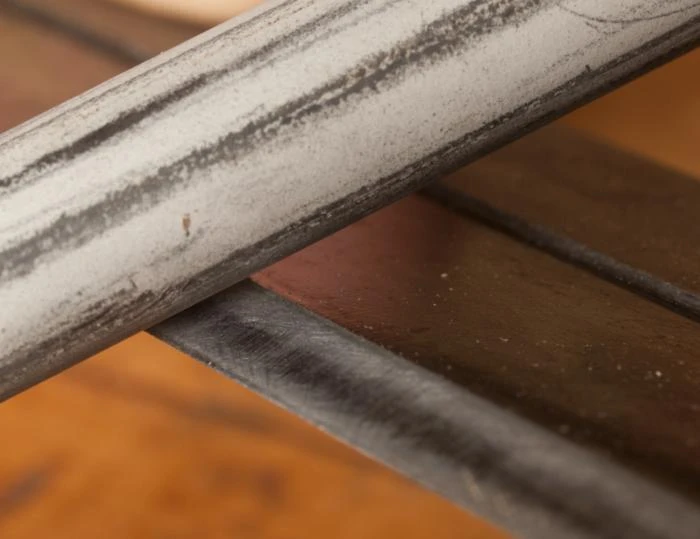

The main draw of the DMT Diamond and Ceramic Steels is how easily they return a dull edge to working order. Instead of holding an unwieldy tool bevel-down against a bench stone, you simply match the bevel angle with the steel, and stroke across the edge. Finish off by holding the steel flat against the back of the blade, and stroke again. The large plastic handle has a guard to keep your hand safe, and the color coded D-Ring makes storage easy.

Unlike a typical butchers steel, DMT Diamond and Ceramic Steels have an abrasive surface that polishes like a stone. Steels are available in three grits, and can be used individually or in sequence depending on the condition of the edge, and your individual requirements.

The Fine Diamond Steel quickly re-sharpens a dull edge. For coarse work this is likely as sharp as you need. You can further refine the edge with either of the two finer steels.

The Extra Fine Diamond Steel provides a higher level of polish to the edge. We see it as a secondary step in sharpening a dull edge, or as a stand alone grit for touching up lightly dulled tools.

For the finest edge use the Ceramic Steel. Use this as a finial step after either of the two Diamond steels, or on its own to maintain an already sharp edge while working. If you wish to go sharper you could use a strop and honing compound but we haven’t found it to be necessary.

DMT sharpening steels have changed how we think about sharpening drawknives. Their ease of use makes it easy to touch up an dulling edge rather than struggle along with a less than prime tool – and that makes working with drawknives a lot more fun. If you ask us, DMT should have named these the DMT MagicWand.

DMT Diamond and Ceramic Steels are Made in the USA.

| option | 12" Diamond Steel – Fine, 12" Diamond Steel – Extra-Fine, 14" Diamond Steel – Fine, 12" Diamond Steel – Ceramic (Finest) |

|---|

Reviews

There are no reviews yet.